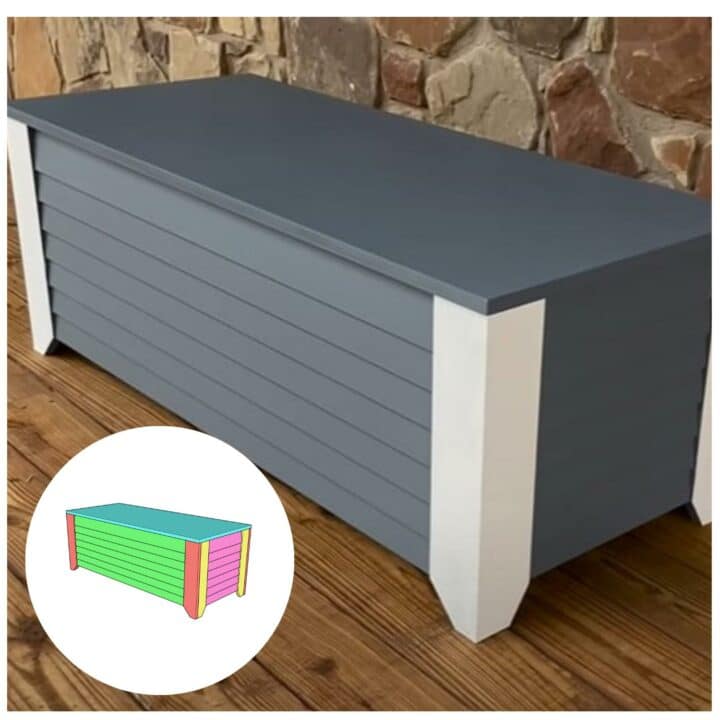

Let’s Construct an Out of doors Storage Bench!

DIY Storage Bench Plans

$9.99

You’ll be able to go quite a lot of alternative ways for materials for this storage bench however I went with an exterior rated MDF known as Armorite. I do know, I do know, it’s usually a cardinal rule that you could’t use MDF in conditions the place it may get moist, as normal MDF swells and is ceaselessly ruined. Simply take a look at how a lot that expanded? This Armorite shouldn’t be solely moisture resistant however can be handled with zinc borate to withstand rot and termites. plus it machines so clear in comparison with normal MDF, that is straight off with none sanding.

I’ve created a set of construct plans to assist making constructing your out of doors storage bench easy.

Supplies I Used to Construct the Out of doors Storage Bench:

Step 1: Organizing Storage Bench Components and Pre-Drilling

I first organized my components on one among my work areas earlier than getting began. To begin the storage bench meeting, I first be a part of collectively the entrance to one of many sides. Since this mission will probably be going outdoors, I’m utilizing an exterior wooden glue on all of the joints then pre drilling and working in a screw. I place my items close to the tip of my workbench in order that I don’t have interference with my drill when pre drilling. After getting the primary facet join, I repeated to attach the opposite.

Step 2: Putting the Backside Between the Storage Bench Partitions

Now earlier than attaching the opposite facet, I’m going to slide within the backside, this could match good between the 2 quick sides. As soon as in place, I run across the three sides and add in screws to connect it. With that achieved, now the ultimate fourth facet of the field may be added in the identical method. Good and straightforward. Remember the fact that I’m making mine for out of doors however you may make yours right into a finish of the mattress bench or a keys toy chest, or something the place you want ornamental storage.

Step 3: Including Legs to Get it off the Floor!

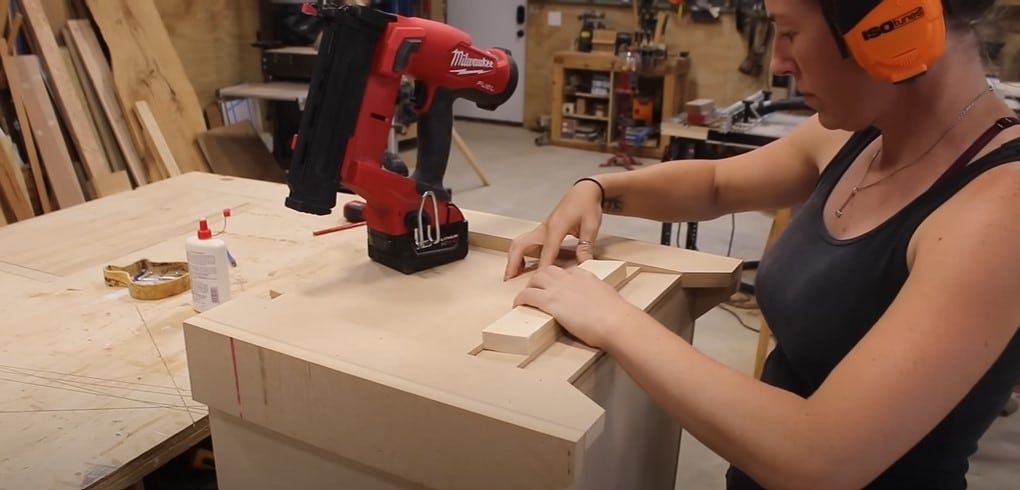

The storage bench physique is completed. Lets add some legs to it. Every thing is created from Armorite and to differentiate the legs some, I took all of the items to the miter noticed first to chop in a slight angle. Now they are often added to the physique. Two items will make up the leg, one is narrower than the opposite in order that each look the identical width as soon as they’re connected. I’m utilizing wooden glue as soon as once more however now converted to utilizing 1 1/4” brad nails as an alternative of screws. To ensure that the legs to return out wanting the identical width, they have to be connected correctly. Which means the small facet must be positioned on first.

Properly whereas I’m fixing my mistake I’d as effectively present you a tip to take away brad nails. As an alternative of clipping them, which by no means leaves them completely flush, I like to drag them out on the bottom. I do that with the big set of Crescent’s sq. nostril pliers. I get a great grip on it then roll the nostril so it pulls the nail up straight. Generally it breaks, however it’s straightforward to get one other grip and pull it the rest method.

Step 4: Putting the Facet and Adorning the Physique

With the quick facet in place, now I can butt this one proper up flush and all the things will come out wanting appropriate. One other method you are able to do it’s by putting the unit on it’s head, yeah truly this fashion is far simpler, as you might have the workbench as a reference level for each of them as an alternative of holding one up whereas attempting to get it flush to the highest.

Lets stand it up and have a look. Sure, good.

Noooow, lets tilt it again down so as to enhance the physique. I’m going with a lap siding look. That is very straightforward to realize. You can begin off with a small strip piece down on the backside, this may create a bump off for the primary siding strip. For all the things on this step I’m utilizing somewhat little bit of wooden glue and brad nails.

Really, I’m going to go forward and decrease this to the ground because it’s simply excessive sufficient to be annoying….or possibly I’m simply quick sufficient. This will probably be a lot simpler to see and use my nail gun at this top however now I simply must seize one among my rolling round stools.

Step 5: Attaching the Lengthy Sides

Okay to begin attaching the siding, this goes fast and straightforward. I laid down the primary strip in order that it’s flush with the trim piece beneath. From there, every strip is reduce to slot in between the legs in order that’s straightforward to get proper however the overlap quantity can fluctuate. To ensure all of them come out constant, I reduce a spacer. Now I simply must line this spacer as much as the underside facet of the earlier strip then nail it in place. I transfer this spacer over to the fitting and repeat. Then to the middle and repeat.

With it caught in place, I throw in a couple of additional ones in between earlier than transferring on to the following and repeat the method once more. If you’re taking pictures in brads, take into account the over lap that every board could have and ensure to put your brads on this zone. That method the following board you lay down will cowl up the nail gap. Oh I don’t know if I discussed earlier than, however the complete physique is created from 3/4” however the slats I created from 1/4”. Armorite is available in various sizes, I’ve even used 1” earlier than on tasks.

One thing else to speak about on this step is adhesive. There may be only a nook of the slat making contact to the physique so you’ll be able to’t use wooden glue. You’ll need to swap to building adhesive and my go to for tasks is DAP Dyna Grip. It’s rated for inside or exterior and a small bead in a couple of locations underneath every new slat works nice.

Step 6: Attaching the Quick Sides

After I received the lengthy facet full, I flip the unit up on finish and repeated with the quick facet. That’s one other distinction with Armorite it takes brad nails a lot cleaner than normal MDF. You don’t get that mushrooming and chipping.

Now, down we go and lets take a look. Properly, that’s fairly darn cute. And so fast!

Step 7: Putting the High of the Storage Bench

Lets maintain the momentum going by including the highest. For my lid I went with a airplane slab of MDF as a result of I plan to have cushions on it for sitting. However know you could possibly all the time reduce in a cool patten or make it appear like particular person boards like I present easy methods to do on an out of doors cupboard. I’ll hyperlink that for you beneath. I line up the highest to the physique in order that it’s flush on the again then pre drill and fasten the hinges.

Step 8: Portray the Storage Bench

Labored like a allure. Notice that I didn’t add a deal with or reduce one in as a result of there’s a inbuilt lip that’s straightforward to seize all alongside the entrance. Let’s break all of those edges and prepare to throw a coat of paint on it! I truly did a complete video on easy methods to correctly paint MDF so I’ll hyperlink to that beneath for those who’re . You’ll be able to undoubtedly roll or brush on paint, however since I’ve an HVLP, that’s what I used to essentially get in all of the nooks and crannies, simply.

After letting it dry I moved it into place and examined it out. Since I knew I’d be sitting my bench up subsequent to the home, I left the lid as is, however another choice is so as to add a sequence to catch the lid from opening too large if you’re putting it someplace with no wall. I can sit the cushions in place, however then once I need to stow them away, I can merely open the lid and put them in till subsequent time.

All in all, this mission solely takes about two hours to finish as soon as the components are reduce. So it’s good and easy however will create a good quantity of storage for a wide range of totally different areas. Do not forget that I’ve a set of plans and a CNC reduce file for those who’re fascinated by constructing your individual.